How to choose your solar panel mount?

Apr 26 , 2022Businesses often ask are carbon steel brackets suitable for solar panel solutions or aluminum brackets are more suitable for solar panel solutions? In response to this problem, As a supplier of solar mounting structures with ten years experience, we will solve this question for you:

1.Solar mounting structure classification.

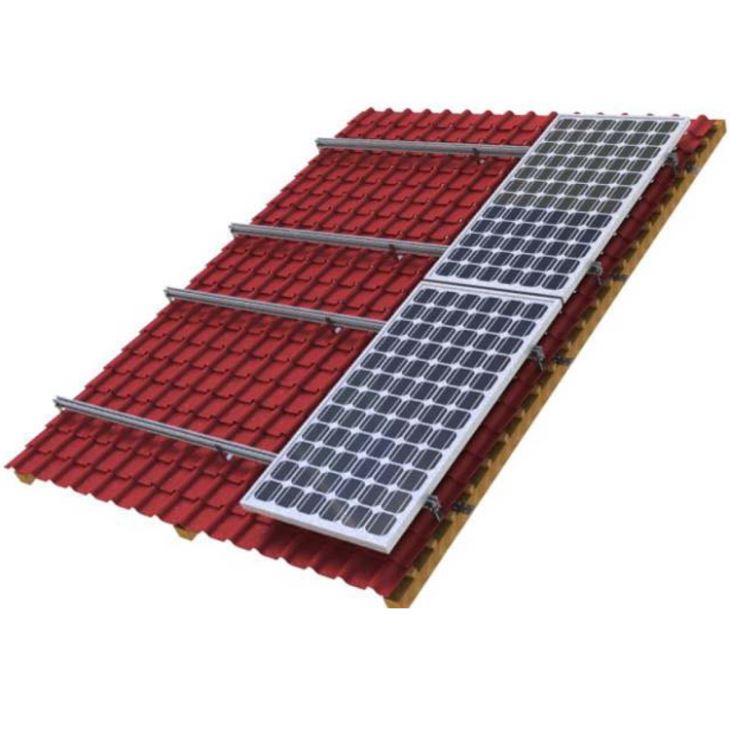

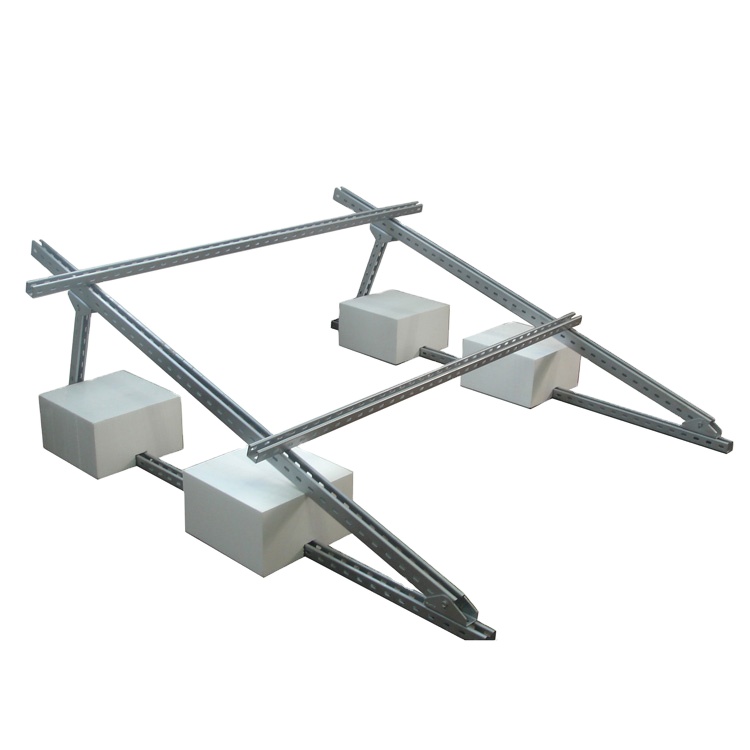

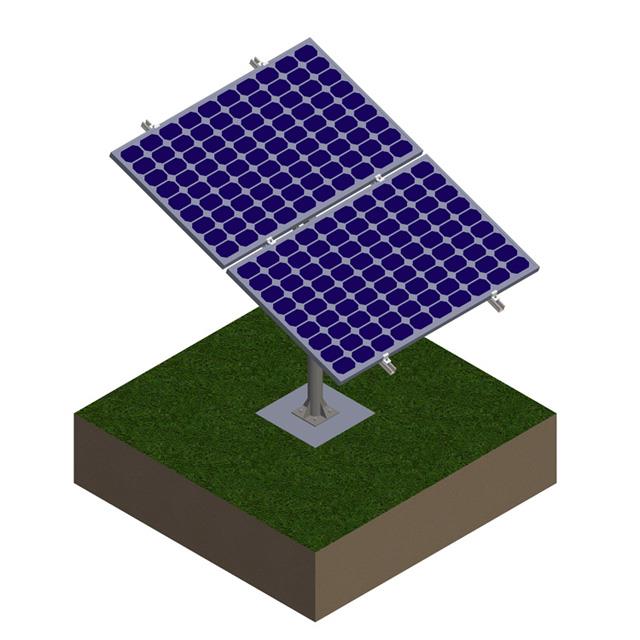

One is the solar panel tilt mount, the second is the flat roof racking, and the third is the ground mount solar racking. All three systems have their own advantages and characteristics.

2.Bracket selection for different installation environments

*For solar panel tilt mount, different roof types use different brackets, such as aluminum hooks for tile roofs. Some tin roofs use metal clamps or L-foot installation solutions. All kinds of brackets have a certain degree of adjustability to meet your various application needs. And the bracket can be installed without destroying the waterproof system of the roof itself.

*Flat roof solar racking. Because the installation ground is relatively flat, it is suitable for large-scale and neat laying and has a variety of stable and reliable foundation connection methods. Common flat roof solutions are solar ballast mounting systems, and fixed tilt racking system.

*Ground mount solar racking systems. This kind of bracket installation method can quickly realize the installation, cooperate with the large-scale ground photovoltaic system, and improve the progress of the construction team of the power station, so it is also the most widely used. Common ground mount racking solutions are stand alone solar power system or solar ground screw structure.

3.How to choose brackets for solar panel mounting structure

At present, solar photovoltaic brackets are divided into carbon steel brackets and aluminum brackets in terms of materials.

Today we mainly share two bracket types carbon steel and aluminum :D

1) The bearing capacity of the steel bracket is high, the installation tools are simple and general, and the steel and stainless steel parts made of structural anti-corrosion materials are used, and the service life is more than 20 years. It is generally used in power stations under ordinary conditions or for components with relatively large forces.

2) Aluminum alloy profiles are light in weight. Generally, roof power stations, strong corrosive environments, and chemical plant power stations that have load-bearing requirements will have better results if they use aluminum as brackets.

3) Under normal circumstances, the basic wind pressure is 0.6kN/m2, the span is less than 2m, and the cost of the aluminum support is 1.3-1.5 times that of the steel structure support.

In small-span systems, (such as color steel plate roofs), the cost difference between aluminum supports and steel structure supports is relatively small, and aluminum is much lighter than steel supports in terms of weight, so it is very suitable for rooftop power stations.

The above are some types and usage characteristics of photovoltaic mounting systems. With the continuous growth of people's awareness of environmental protection, the photovoltaic industry will gradually spread to our lives, so we must be careful when choosing solutions to make our lives more convenient and fast.

You should yearn and get one.

If you don’t have any ideas, contact us now.