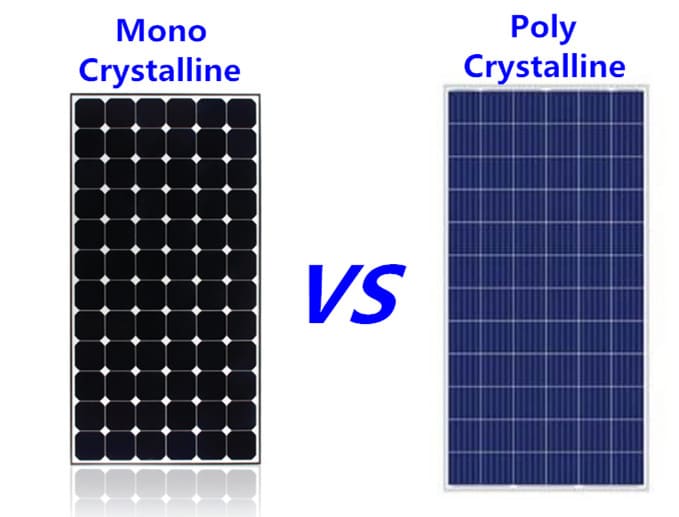

DIFFERENCE BETWEEN MONO CRYSTALLINE AND POLY CRYSTALLINE SOLAR PANELS

Jun 28 , 2022

To consult different manufacturers, the answers are similar.

Let's see what the difference is~

The cells in a mono crystalline panel are made from a single crystal of silicon. The crystal structure is perfectly homogeneous. The crystal structure is perfectly homogeneous, which gives it its characteristic color, which is usually perfectly black.

On the contrary, the cells of a poly crystalline solar panel are made up of several silicon and do not have a completely homogeneous color, it is closer to blue.crystals of different sizes.

2. Which is better optional for us?

1) Conversion efficiency:For the same area, The conversion efficiency of the mono crystalline solar panels is about 15%, and the highest is 24%; while the poly crystalline solar panels is about 12%.

2)Service life:Mono solar panel is usually encapsulated by tempered glass and waterproof resin, which is strong and durable, so its service life is longer than poly crystalline, generally up to 15 years, max up to 25 years.

3) Manufacturing cost: Compared with the Mono panel, the poly crystalline material is easy to manufacture, saves power consumption, and has a lower total production cost. Of course, with the improvement of the manufacturing process, the production cost of mono crystalline solar panels is also gradually decreasing.

4)Power production:

In a Mono crystalline BR solar panel mounting system, production starts a little earlier in the day and stops a little later at night.

In a Poly crystalline solar panel, power production will start later in the day.

3. Purchasing Considerations

1) Look at the material

Mono crystalline panel and poly crystalline can also be distinguished from the appearance.

The four corners of mono crystalline have truncated corners, which are mostly arc-shaped, blue-gray, and the texture is relatively simple; the four corners of poly crystalline are square corners, and the surface is mostly gray-white with impurities.

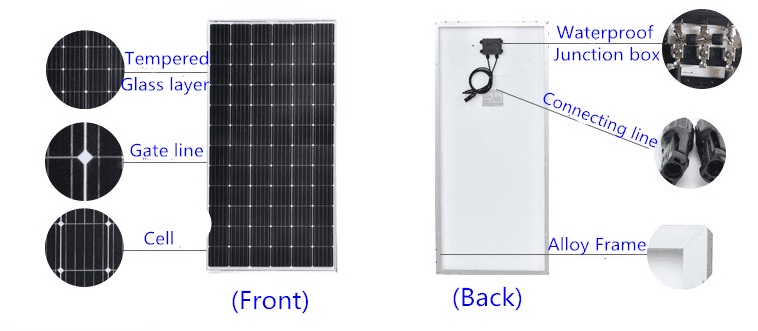

2) Look at the back

When purchasing, the back of the panel is often overlooked. This place is mainly to observe the pressure-bearing effect of the panel. After applying force to the back, if there is no unevenness such as air bubbles, wrinkles, etc., it means that the panel is qualified

3) Look at the frame

Generally speaking, the frame of the panel is polished by mechanized operation, so as to better ensure its accuracy and become a strict rectangle. Otherwise, the frame will not be in close contact with the solar panel, reducing the firmness and affecting the service life of the solar panel.

4) Look at the workmanship

In addition to the above, it is also necessary to check its workmanship. The solar panel is composed of small pieces of solar cells welded together, which should be cut as a whole.

Schematic

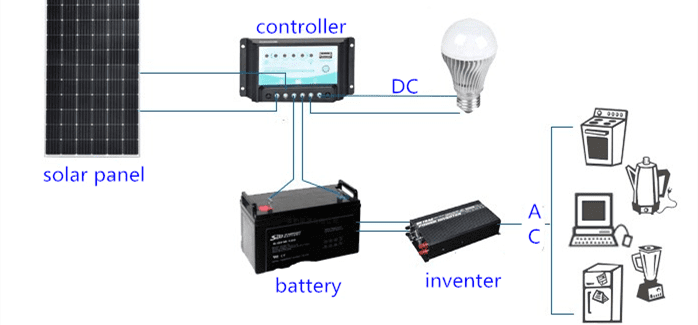

Connection diagram

With all these, you can now go ahead and build your solar panel system with no difficulties. In case you want to learn more about solar mounting systems, feel free to contact us.

And by the way, here are more resources you can learn more about PV mounting system: